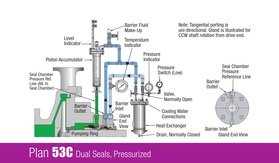

Plan 53C - Dual seals, pressurised - Liquid barrier through a heat exchanger with differential pressure tracking piston accumulator

Features

Description: Plan 53C uses a piston accumulator to provide pressure to the system. It uses a reference line from the seal chamber to provide a constant pressure differential over the chamber’s pressure. A water- or air-cooled heat exchanger provides for barrier fluid cooling. Flow is induced by a pumping ring.

Advantages: Provides a tracking system to maintain barrier pressure above seal chamber pressure.

General: The heat exchanger can be a water-cooled unit, an air-cooled unit, or utilize finned tubing based upon the system heat load. The reference line to the accumulator must be tolerant of process contamination without plugging.